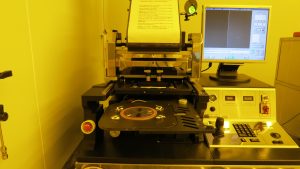

- Wafer/ Substrate Parameter : Up to 4 Inch Substrate and Small Wafer pieces can be handled

- Mask Parameter : Can handle up to 5 Inch ( 4 Inch Area Exposable).

- Alignment Accuracy : 0.5µm for Top Side (with 20x). 1µm for Bottom Side (with 20x).

- Separation/ Proximity Adjustment : A maximum of 300µm adjustable in 1µm steps

- Contact Force between Mask and Substrate : Adjustable from 0.5N – 40N.

- Contact Modes : Soft, Hard, Vacuum, Vacuum + Hard, Proximity

- Printing Resolution : 3µm in Proximity, 1µm in Vacuum + Hard Contact

- Lamp House : Standard NUV of 365nm and Standard Lamp Power of 500W

ABM Mask Aligner_Annexe1

ABM Mask Aligner is a “SEMI-AUTOMATIC” Contact Photo-Lithographic Alignment and Exposure Tool. It also has the Capability of Front to Back Alignment of Patterns and Aligning wafer stack for the Anodic bonder. Recipes for different Exposure types and Contact Modes can be Pre-Written and is very User friendly. The equipment for Optical Lithography allows for selectively masking and exposure of certain areas of

the sample substrate using a ”MASK” and ”SET OF MASK”. Masks are realized in advance by Laser Writer by Etching a Thin Metallic Layer deposited onto a special Glass Slide.

Acid Hood (Annexe 2)

Anelva RF Sputtering – Annexe-1

RF Sputtering runs an energetic wave through an inert gas in a vacuum chamber which becomes ionized. The target material or cathode of the desired material is bombarded by these high energy ions sputtering off atoms as a fine spray covering the substrate to be coated. RF Magnetron sputtering uses magnets behind the negative cathode to trap electrons over the negatively charged target material, so they are not free to bombard the substrate, allowing for faster deposition rates.

Anelva RIE System-Annexe-1

Anelva RIE DEM-451 parallel plate, 13.56 MHz system used for etching with tetrafluoromethane (CF4). This system etches substrates placed on the cathode by accelerating active (highly reactive gas) ions dissociated in discharged plasma in the electric potential drop region. The system is used primarily for etching Si, SiO2 and polymide films.

Chemical Mechanical Polishing (CMP -Annexe-1)

Chemical-mechanical polishing (CMP) is often associated with chemical-mechanical planarization which is a polishing process assisted by chemical reactions to remove surface materials. CMP is a standard manufacturing process practiced at the semiconductor industry to fabricate integrated circuits. When the purpose is to remove surface materials, it is referred to as chemical-mechanical polishing. However, when the purpose is to flatten a surface, it is referred to as chemical mechanical planarization. CMP is a tribochemical process because of the synergy between friction and corrosion.

E-Beam Evaporator_Annex

HHV Co-Sputter Oxide Tool _Annexe 3

Sputter deposition is a widely used technique to deposit thin films on substrates. The technique is based upon ion bombardment of a source material, Ion bombardment results in a vapour due to a purely physical process; sputter deposition is the use of a magnetron source in which positive ions present in the plasma of a magnetically enhanced glow discharge bombard the target. The target can be powered in different

ways, ranging from dc for conductive targets, to RF for nonconductive targets, to a variety of different ways of applying current and/or voltage pulses to the target.

HHV Glove Box Sputtering_Annex

Sputter deposition is a widely used technique to deposit thin films on substrates. The technique is based upon ion bombardment of a source material, Ion bombardment results in a vapour due to a purely physical process; sputter deposition is the use of a magnetron source in which positive ions present in the plasma of a magnetically enhanced glow discharge bombard the target. The target can be powered in different ways, ranging from dc for conductive targets, to RF for nonconductive targets, to a variety of different ways of applying current and/or voltage pulses to the target.

HHV Sputter Coater 2- Annexe 1

Sputter deposition is a widely used technique to deposit thin films on substrates. The technique is based upon ion bombardment of a source material, Ion bombardment results in a vapour due to a purely physical process; sputter deposition is the use of a magnetron source in which positive ions present in the plasma of a magnetically enhanced glow discharge bombard the target. The target can be powered in different

ways, ranging from dc for conductive targets, to RF for nonconductive targets, to a variety of different ways of applying current and/or voltage pulses to the target.

HHV Sputter Metal Coater1- Annexe 1

Sputter deposition is a widely used technique to deposit thin films on substrates. The technique is based upon ion bombardment of a source material, Ion bombardment results in a vapour due to a purely physical process; sputter deposition is the use of a magnetron source in which positive ions present in the plasma of a magnetically enhanced glow discharge bombard the target. The target can be powered in different ways, ranging from dc for conductive targets, to RF for nonconductive targets, to a variety of different ways of applying current and/or voltage pulses to the target.

HHV Sputter Tool (Nitride)_Annexe 3

Sputter deposition is a widely used technique to deposit thin films on substrates. The technique is based upon ion bombardment of a source material, Ion bombardment results in a vapour due to a purely physical process; sputter deposition is the use of a magnetron source in which positive ions present in the plasma of a magnetically enhanced glow discharge bombard the target. The target can be powered in different ways, ranging from dc for conductive targets, to RF for nonconductive targets, to a variety of different ways of applying current and/or voltage pulses to the target.

Lindberg Furnace (Annexe-1)

Annealing is a heat treatment procedure involving heating the materials and holding it at a certain temperature (annealing temperature), followed by controlled cooling. Annealing results in relief of internal stresses, softening, chemical homogenizing and transformation of the grain structure into more stable state.These operations are carried out by heating to the required temperature followed by soaking at this temperature for sufficient time to allow the material to stabilize followed by slow cooling (except for solution annealing) at a slow and often times-controlled rate.

Optical Lithography-EVG 620

EVG620 is a “SEMI-AUTOMATIC” Contact Photo-Lithographic Alignment and Exposure Tool. It also has the Capability of Front to Back Alignment of Patterns and Aligning wafer stack for the Anodic bonder. Recipes for different Exposure types and Contact Modes can be Pre-Written and is very User friendly. The equipment for Optical Lithography allows for selectively masking and exposure of certain areas of the sample substrate using a ”MASK” and ”SET OF MASK”. Masks are realized in advance by Laser Writer by Etching a Thin Metallic Layer deposited onto a special Glass Slide.

Solvent Hood (Annexe 2)

Process Capability

All processes using Acetone, IPA or methanol. This bench is for metal liftoff, Litho mask cleaning and KOH silicon etch (LEVEL 4)

Tool Capability

It has petridishes and ultrasonic bath for lift off process. Heater and beakers are provided for KOH etch of cut pieces. The bench is also fitted N2 dryer.

Vacuum Annealing Tool (Annexe1)

Vacuum annealing is a heat treatment process where materials are heated and then slowly cooled under vacuum conditions to relieve stress, alter microstructure, and improve material properties. This process is particularly useful for metals and other materials where surface oxidation or contamination is undesirable, as the vacuum environment prevents reactions with oxygen and other gases.

VR Tech Sputter tool – Annexe-1

Sputter deposition is a widely used technique to deposit thin films on substrates. The technique is based upon ion bombardment of a source material, Ion bombardment results in a vapour due to a purely physical process; sputter deposition is the use of a magnetron source in which positive ions present in the plasma of a magnetically enhanced glow discharge bombard the target. The target can be powered in different ways, ranging from dc for conductive targets, to RF for nonconductive targets, to a variety of different ways of applying current and/or voltage pulses to the target.

VR Tech Thermal Evaporator_Annex

Substrate type: Si, Glass, Sapphire, Ceramic, Metal, etc.

Substrate holder: Up to 4″” dia with substrate rotation and Heating (up to 600°C).

Substrate heating: No

Pumping Combination: Rotary + Turbo

Uses tungsten or molybdenum filaments to evaporate the materials.

Uses Quartz crystal is used to monitor the thickness of the deposited film