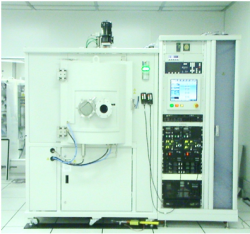

• E-Beam evaporation is sourced from Tecport.

• There are two electron guns and an Ion gun.

• EB guns has two hearths. Hearth associated with EB gun-1 has four 25 cc pockets and the one associated with EB gun-2 has six 15 cc pockets.

• One 4 pocket hearth and one 6 pocket hearth.

• Pop-Top source

• Max Power 10kW

• Accelerating Voltage 4-8 kV

• Beam deflection 270deg

• Emission Current 0-1.5A

• Programmable sweep controller.

• Temescal Crucible indexer.

• Substrate holder {6, 4, 3, 2 inch diameter}.

• Planetary rotation with four holders.

• Inficon IC6 deposition controller.

• Ultimate Pressure ~2E-7 Torr.

• Process Control using Symphony software.

• Deposition rates from 1 Å/s to 199 Å/s.

• Ion-assisted deposition is also possible.